Metallurgical Testing Laboratory Service

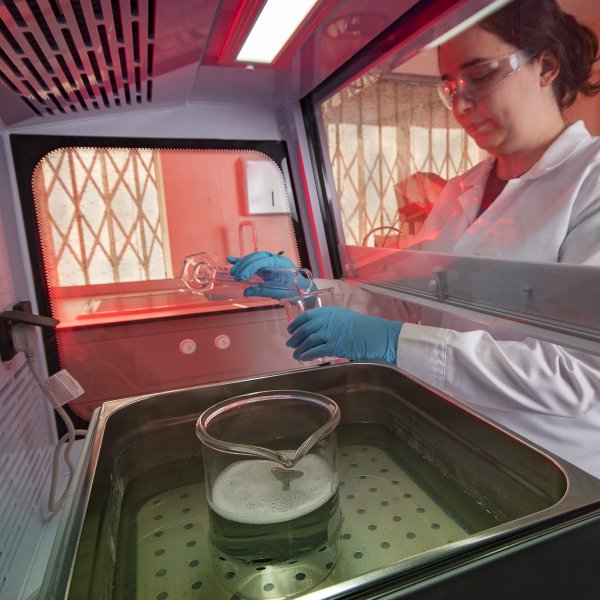

AHT has a state-of-the-art metallurgical test laboratory, enabling onsite Nadcap conforming furnace qualification testing and monthly furnace control metallurgical testing, required for maintenance of aircraft approved furnaces. We are required to test for evidence of: High Temperature Oxidation (HTO), Eutectic Melting (EM), Cladding Diffusion (CD) and Intergranular Attack (IGA).

Our Metallurgical Testing Laboratory Service

- State of the art metallurgical test laboratory

- Nadcap conforming furnace qualification testing

- High Temperature Oxidisation (HTO)

- Eutectic Melting (EM)

- Cladding Diffusion (CD)

- Intergranular Attack (IGA)

- SDAS Measurements

Tests include: Chemical Analysis, Physical Testing, Corrosion Testing, Mechanical Testing, Microstructural Analysis and Non-Destructive Testing.

What Is Metallurgical Testing?

Metallurgical testing is the analysis of materials used in the construction of various structures, machines, and products. It is a broad field that encompasses a range of techniques and tests to evaluate the physical, chemical, and mechanical properties of metals and alloys.

These tests are performed to determine the suitability of materials for various applications, to optimize their performance, and to ensure their quality and safety.

Metallurgical testing is an essential part of the manufacturing and construction industries. It helps to ensure the quality and safety of materials used in a wide range of products and structures, from automobiles and airplanes to buildings and bridges.

Metallurgical Testing Resources

Types Of Metallurgical Laboratory Testing

There are many types of metallurgical testing, each with a specific purpose. Some common tests include:

Chemical Analysis:

This test is used to determine the chemical composition of a material. It helps to identify the various elements present in the material and their proportions. Chemical analysis can be performed using various techniques such as spectroscopy, titration, and wet chemical methods.

Physical Testing:

This test is used to determine the physical properties of a material, such as its density, conductivity, and melting point. Physical tests can be performed using a variety of methods, including gravimetric analysis, calorimetry, and thermometry.

Corrosion Testing:

This test is used to evaluate the corrosion resistance of a material. It helps to determine the material’s susceptibility to corrosion and its ability to withstand the effects of corrosion over time. Corrosion tests can be performed using a variety of methods, including electrochemical techniques and exposure tests.

Mechanical Testing:

This test is used to evaluate the mechanical properties of a material, such as its strength, ductility, hardness, and toughness. Mechanical tests can be performed using a variety of methods, including tensile testing, compression testing, impact testing, and fatigue testing.

Microstructural Analysis:

This test is used to study the microstructure of a material, which refers to the arrangement of atoms and molecules at the microscopic level. Microstructural analysis can be performed using techniques such as microscopy, diffraction, and spectroscopy.

Non-Destructive Testing:

This test is used to evaluate the properties of a material without causing any damage or “destruction” to it. Non-destructive tests can be performed using techniques such as ultrasonic testing, radiographic testing, and eddy current testing.

Metallurgical Testing Lab: Blogs, News & Resources

We have a list of helpful blogs on the subject of Metallurgical Testing Blogs, feel free to search our knowledge base and our blogs to familiarise yourself with the processes we undertake during the Metallurgical Testing Lab service.

Blogs:

Post Heat Treatment: Corrosion Testing

Microstructural Analysis: Crucial For Alloy Perfection

Metallurgical Lab Testing FAQ’s

Metallurgical test laboratories offer a wide range of tests, including metallography, hardness testing, tensile testing, impact testing, chemical analysis, corrosion testing, microstructure analysis, and dimensional inspection.

Metallurgical testing can benefit your business or industry by ensuring the reliability and safety of materials and products, aiding in quality control and assurance, supporting research and development efforts, troubleshooting failures, and improving overall process efficiency.

Yes, metallurgical test laboratory services cater to a variety of metals and alloys, including steel, aluminium, copper, titanium, nickel, and their respective alloys. These services can be customized based on the specific requirements of your material.

The turnaround time for test results can vary depending on the complexity of the tests, the workload of the laboratory, and other factors. However, we strive to provide prompt and timely results to meet our clients’ needs.

Absolutely. Metallurgical test laboratories possess expertise in material characterization and can provide guidance on selecting the most suitable materials for your specific application, considering factors such as mechanical properties, corrosion resistance, and temperature requirements.

Yes, metallurgical testing is often employed in failure analysis investigations. Through examination of the material’s microstructure, chemical composition, and mechanical properties, the laboratory can identify the root cause of failures and provide recommendations for prevention.

We can accommodate customized or specialised testing requests. It is advisable to discuss your specific needs with the laboratory to determine the feasibility of conducting such tests and any additional requirements or costs involved.

To select a reliable metallurgical test laboratory, consider factors such as accreditation, experience, reputation, technical capabilities, adherence to industry standards, turnaround time, customer reviews, and client references. Choosing a reputable laboratory ensures accurate and reliable test results.