Alloy Test Lab: Microstructural Analysis

In the dynamic world of engineering, where precision and performance are paramount, understanding the intricate microstructures of alloys is akin to decoding the blueprint of innovation. In this article, we delve into the significance of microstructural analysis and its pivotal role in shaping the landscapes of aerospace and automotive industries.

What Is Microstructural Analysis?

At its core, microstructural analysis delves into the microscopic arrangement of atoms and molecules within a material. It is a fundamental aspect of metallurgical testing, providing invaluable insights into the properties and performance of alloys. Employing an array of advanced techniques ranging from microscopy to diffraction and spectroscopy, microstructural analysis unveils the hidden characteristics of materials, enabling engineers to optimise their designs and processes.

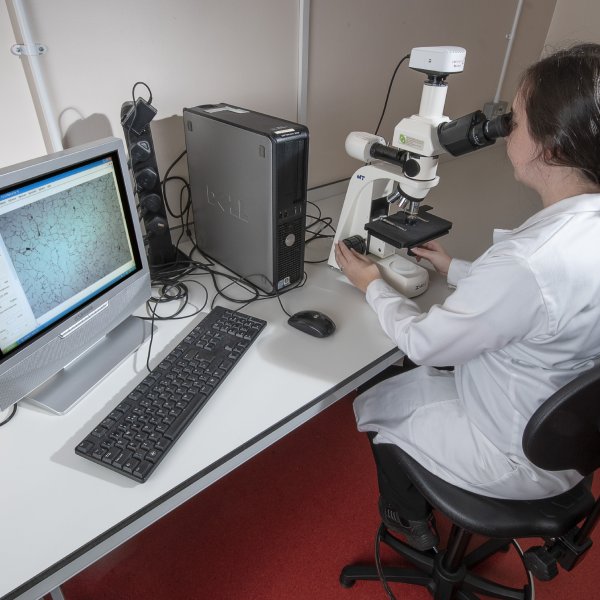

Traditionally, microstructural analysis relied on optical microscopes coupled with meticulous metallurgical preparation. However, the landscape has evolved dramatically over the past few decades. With the advent of advanced technologies like digital image processing and computer vision, coupled with tools such as Scanning Electron Microscopes (SEM), the analysis has become more precise, efficient, and insightful than ever before.

The importance of microstructural analysis cannot be overstated. It serves as a window into the soul of a material, offering insights that are impossible to glean through mere surface examination. By scrutinising the arrangement of atoms and molecules, engineers can anticipate how a material will behave under various conditions, paving the way for more informed decision-making in design, manufacturing, and quality control processes.

The Significance of Microstructural Analysis in Engineering Sectors

In the realm of aerospace and automotive industries, where precision and reliability are non-negotiable, the importance of alloy microstructures cannot be overstated. Every component, from turbine blades to automotive chassis, relies on the inherent properties of alloys to withstand extreme conditions and deliver exceptional performance. The microstructure serves as a blueprint, dictating mechanical strength, thermal stability, and corrosion resistance, thus shaping the overall functionality and longevity of critical components.

Let’s delve deeper…

Microstructural Analysis In Aerospace Materials

In aerospace engineering, where every ounce matters and safety is paramount, the choice of materials is critical. By leveraging microstructural analysis, engineers can identify materials with optimal strength-to-weight ratios, ensuring that aircraft components are robust yet lightweight. Moreover, insights gained from microstructural analysis can help in identifying potential weak points or vulnerabilities in materials, allowing for preemptive reinforcement or redesign.

Microstructural Analysis In Automotive Materials

Similarly, in the automotive industry, where performance and durability are the cornerstones of success, microstructural analysis plays a pivotal role. Whether it’s enhancing the structural integrity of engine components or fine-tuning the composition of alloys for chassis construction, microstructural analysis empowers engineers to push the boundaries of innovation while maintaining uncompromising quality and reliability.

Metallurgical Testing:

At AHT, our metallurgical test laboratory is equipped with a comprehensive suite of services tailored to meet the diverse needs of our clients:

1. Chemical Analysis: By deciphering the chemical composition of materials, chemical analysis unveils their elemental makeup and proportions.

2. Physical Testing: Determining the physical properties of materials is essential for assessing their suitability for specific applications.

3. Corrosion Testing: Corrosion testing procedures evaluate the corrosion resistance of alloys, enabling engineers to select materials that can endure the rigors of their intended environments.

4. Mechanical Testing: Understanding the mechanical behavior of alloys is crucial for predicting their performance under varying loads and conditions.

5. Microstructural Analysis: Microscopy, diffraction, and spectroscopy techniques to evaluate important microstructures.

6. Non-Destructive Testing: Testing without affecting the structural integrity of the product, services like Dye-Pen are non-destructive testing.

Alloy Test Lab Service:

To learn more about how our test lab can benefit the output of your components, materials and castings you can click here. Got a question? Feel free to email one of our friendly and knowledgeable team. Alternatively you can call us to speak to someone direct and even get yourself a free, non-obligatory quote.