When Alloy Heat Treatment (AHT) was established in 1974 it became the first UK company dedicated to the heat treatment of aluminium alloys. To satisfy ever increasing demands for its wide range of services, the Dudley, West Midlands based subcontractor has continuously expanded its facilities, invested in the best available heat treatment plant and increased its skilled workforce.

The busy company now operates 19 furnaces that provide the capacity to keep pace with customer demand. Now regarded as a technical leader in its chosen field AHT has the ability to heat-treat a wide variety of aluminium products, from sheet metal to large sand castings, ranging in weight from just a few grams to over 2.5 tonnes.

The NADCAP, AS 9100 accredited business, has achieved preferred supplier status with many aerospace primes and enjoys long term relationships with companies such as Rolls Royce, BAe and Airbus. In addition, AHT has assisted many automotive tier one and sub-tier suppliers in their adoption of aluminium in areas such as the integration of lightweight engine and suspension components. The company also enjoys a strong presence within the challenging motorsport sector and works with teams such as Mercedes and McLaren.

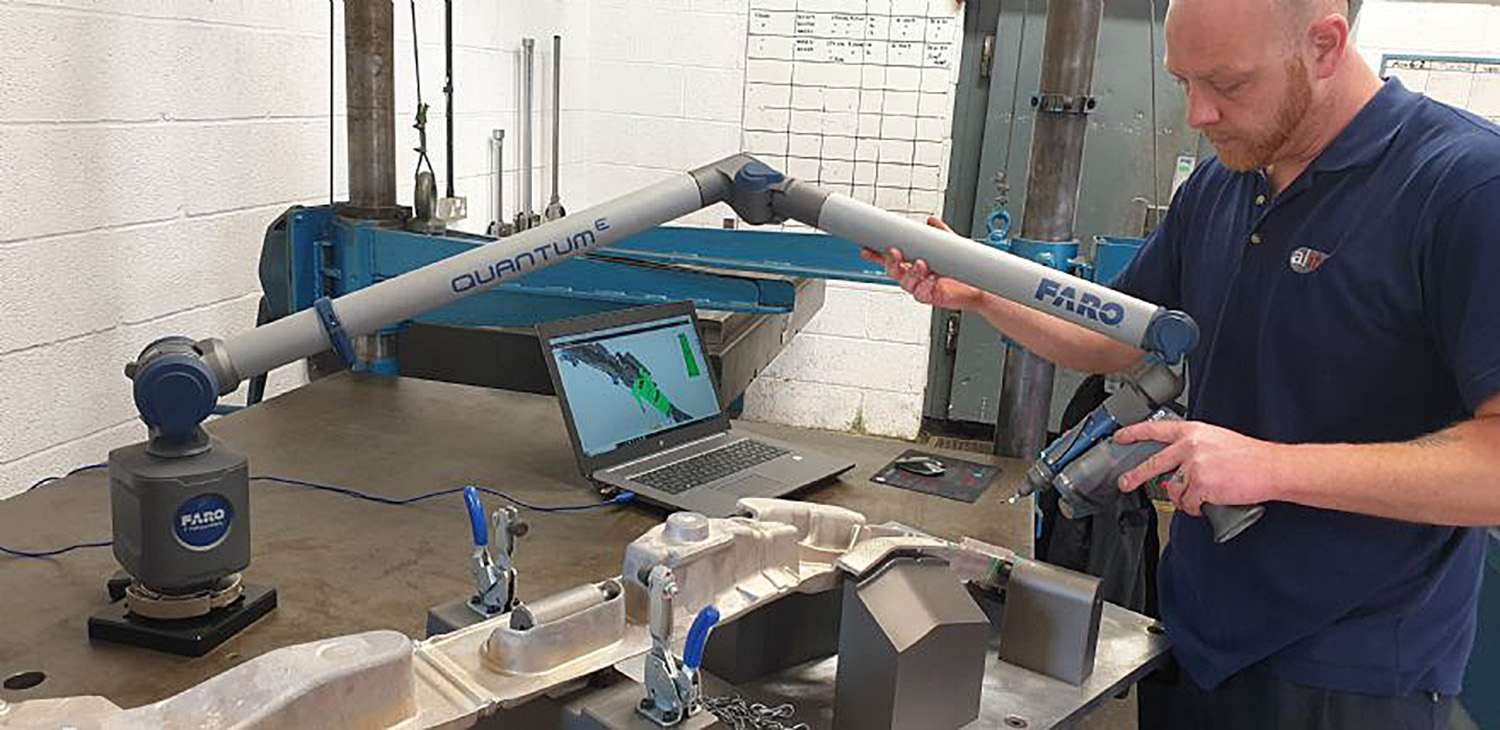

To complement its heat-treatment processes, AHT offers services such as solvent degreasing and dye-penetrant flaw detection. Also, as unwanted distortions can occur in intricate aluminium products due to the rapid heat transfer from the quenching process, the business operates a setting department that removes distortion in the treated condition whilst products remain ductile. To help further increase AHT’s setting department precision capabilities and to speed up the throughput of its important work, an advanced Quantum E ScanArm was recently purchased from FARO UK.

AHT Director Sales & New Projects Manager, Ian Perks explained. “Although all at AHT are committed to providing an efficient service to our clients and to remaining commercially competitive, the quality of the services that we provide and the premium standard of the heat-treated components we deliver to our customers, are of paramount importance to us.

“As a vital aspect of our strict quality regime, we perform regular internal audits to ensure that we continually comply with the requirements of AS 9100:Rev D (BS EN 9100:2018) incorporating BS EN ISO 9001:2015. We also use the data generated by our audits as the basis for making improvements to our quality management system.

“In addition to frequently investing in the best possible heat treatment plant, given the nature of our customers and the challenging technical demands they place on us, we also believe in regularly updating our important material testing and dimensional quality control equipment.

“Owing to the speed and precision an advanced ScanArm type device could provide, for many years we have felt that such a device had a part to play in our organisation. Therefore, as our workload grew, recently, we finally committed to placing an order. As we were aware of FARO’s reputation for innovation and for being the market leader in this technology, we didn’t consider purchasing any other brand of laser scanner.

“After considering several FARO models, due to its speed, ease of use and impressive accuracy specification, we chose the Quantum E ScanArm. Also, given that it will be used in a working environment, it helped our decision that the Quantum E has an impressive IP rating and is resistant to the ingress of dust and fluids.

“Given that this is our first FARO ScanArm, we sent two of our operators on a FARO course which enabled them to pick up the fundamental of the FARO Quantum E and software. As our new FaroArm is now in daily use, our two trained staff members have quickly become competent in the ScanArm’s use, and they will soon be training a further 5 members of staff in its use.

A vitally important aspect of our services is our first-class setting department, here, our skilled operators remove distortion from components following the quenching process. In addition to improving our precision capabilities in this area, our new Quantum E has considerably speeded up these processes. The scans made by our new FARO equipment enables precise corrections to be made to components, then by re-scanning them, our staff are able to ensure that components adhere to customers’ requirements. Also, as our setting fixtures are unable to detect the distortions that occur in a few of our parts, through the use of our new FARO ScanArm we can new guarantee that these parts will machine successfully.”

FARO is recognised as the world’s most innovative portable CMM manufacturer and for more than 35 years the company has designed and sold the most trusted metrology arm technology.

The QuantumE FaroArm, as purchased by AHT, represents the ideal portable solution for business that are looking for a cost-effective, user-friendly and efficient factory inspection system. The advanced FARO device has been tested to withstand the harshest shop-floor environments and to provide accurate and reliable measuring results that give manufacturers maximum confidence in their quality assurance processes.

When a FARO Laser Line Probe option is attached to a FaroArm, it becomes a super-efficient ScanArm, capable of delivering up to a remarkable 600K metrology points per second. AHT specified a FARO Quantum E ScanArm fitted with a Prizm Colour Laser Line Probe – the world’s only colour laser line probe for portable measurement arms. When used in combination with the Prizm Laser Line Probe, the Quantum E delivers uncompromising levels of performance across all applications that require accurate colour point cloud data capture.

Reflecting FARO’s leading position in the design and manufacture of measuring arms, Quantum FaroArms are the first Arms in the market that are certified against ISO 10360-12:2016 for articulated arms, setting a new industry performance bar, and ensuring maximum measurement consistency and reliability.

Given the size of AHT’s facility and the requirement to occasional perform measurement and scanning routines in remote areas, it helped that the Quantum E ScanArm benefits from market-leading portability and speed of set-up. In addition, the use of dual hot-swappable batteries supports prolonged cable-free operation, enabling the device to be used for an extended period without the need for external power.

Matching the Quantum E’s impressive speed of operation, the ScanArm’s sophisticated new electronic design guarantees optimal wireless operation for scanning and probing, allowing gathered data to be transmitted via high-speed wireless methods across the entire manufacturing floor.

Ian Perks concluded. “So successful has our use of our new FARO Quantum E been, we now anticipate a much quicker ROI than we originally anticipated. In addition to proving to be the perfect choice for the measurement and scanning tasks we purchased it for, since using our new ScanArm, we have found numerous other uses for it across our entire site. It really helps that our Quantum E is portable and quick to set up, as we are now looking to offer an efficient scanning service, not only to our heat treatment customers, but also to customers that require a scanning service without our heat treatment services.”