50 Years Of Alloy Heat Treatment In The Light Metal Industry

Welcome to Alloy Heat Treatment’s milestone celebration! For over five decades, Alloy Heat Treatment has been at the forefront of the light metal industry, specializing in alloy and aluminium heat treatment for the aerospace and automotive sectors.

As we mark our 50th year of service, we reflect on our journey of innovation, excellence, and unwavering commitment to quality. From our humble beginnings in 1974 to our current position as a trusted leader in the field, Alloy Heat Treatment has continuously pushed boundaries, embraced cutting-edge technology, and exceeded industry standards.

1974 – The Beginning

Alloy Heat Treatment Founded. Blackprint Ltd T/A Alloy Heat Treatment began its business in a modest sized industrial unit in Timmis Road, Lye, Stourbridge in 1974.

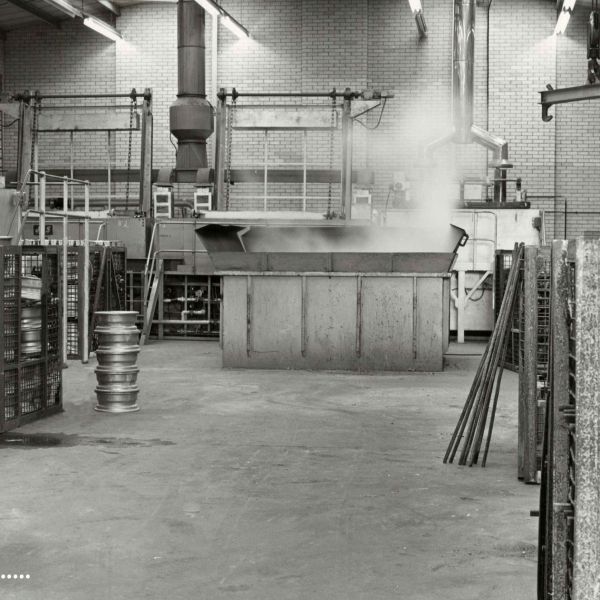

1982 – first Rapid Quench

AHT Installs 1st Rapid-Quench Plant. In 1982 AHT installed its first rapid-quench drop-bottom heat treatment line, supplied by the JLS Engineering Co Ltd. This facility introduced AHT into the Aerospace industry.

1988 – Larger Premises – Move to Dudley

By 1988 AHT’s business had outgrown the Lye premises and so relocated to Unit 18, Grazebrook Industrial Park, Dudley. A larger rapid quench oven was installed, which triggered a number of further capital investments in the coming years.

2002 – Expansion – Block 6 Added

By 2002 AHT’s business had exceeded the capacity of Unit 18 so an additional unit – Block 6, on the same site was added. This came with a larger office block and became the main commercial hub, with Unit 18 now being dedicated to aircraft work.

2003 – Schlick Hanger shot blast machine

A Schlick Hanger shot blast machine was installed in response to customer demand, which produces a matt-silver consistent surface to cast aluminium products.

2003 – Automated Line – Another 4 Drop-Bottom Ovens

In 2003 AHT commissioned JLS to install a line of 4 drop bottom ovens. This fully automated line with shared load bogie and hot water quench tank comprised 2 x electric and 2 x gas ovens.

2004 – AHT achieves Nadcap accreditation

Opening the AHT doors to continued access to the world of Aerospace heat treatment, AHT achieves the prestigious Nadcap approval award.

2006 – Dye Penetrant Inspection Line –

A Dye Penetrant Inspection Line was installed in response to customer demand. This key process checks heat treated castings for post quench surface indications, which become prevalent after heat treatment. Most automotive OEMs insist on this process.

2007 – Automated Line

Another gas fired oven added to the line. This addition was considered at the planning stage of the Automated Line, and due the success of the line, Oven 5A was added.

2010 – SED compliant Solvent Degreaser

A state-of-the-art SED compliant degreaser was installed to meet Aerospace, DEFRA and REACH compliance criteria.

2012 – Large Gas Fired Top Loading Oven

A large gas fired top loading oven was due to the demand for quenching larger products, thus, expanding the AHT porfolio.

2014 – Alltherm

Alloy Heat Treatment becomes a major shareholding of Alltherm, and becomes a manufacturer of furnaces to the open market, which opened the AHT doors for a number of capital investments in the rapidly expanding Aerospace heat treatment business, the first being an installation of rapid quench facility and a top loading electric oven, conforming to AMS2750 Class 1.

2015 – Aerospace Heat Treatment Increased Demand.

Due to increased demand for Aerospace heat treatment, AHT, under the banner of Alltherm, further expands it’s Aerospace heat treatment facilities, by manufacturing and installing a rapid quenching line, consisting of 2 rapid quench ovens, with water and polymer quench tanks.

2016 – Increased Project Volume

AHT, continues to invest, and under the banner of Alltherm, the Company’s largest ever, fully automated heat treatment facility, including water and polymer quench tanks, was installed and commissioned.

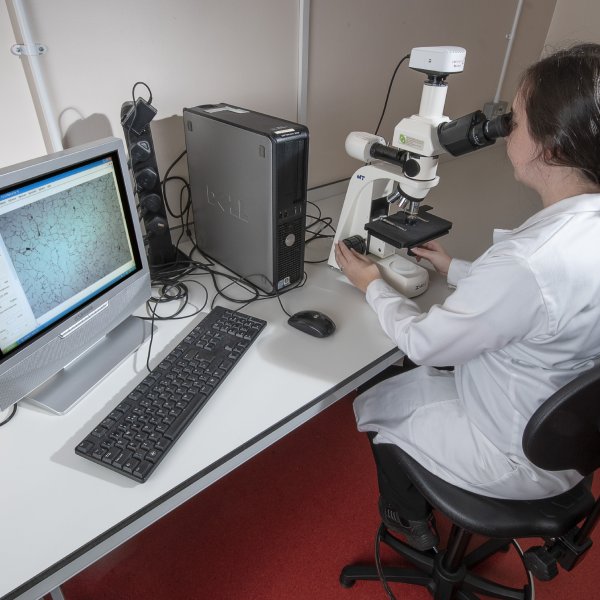

2017 – Metallurgical Test Laboratory

To keep up with the ongoing maintenance of our Aerospace approvals, AHT install a brand new state-of-the-art metallurgical test laboratory. This in-house facility and qualified professionals enable AHT to ensure impeccable Aerospace standards are maintained.

2019 – The introduction of FARO Arm.

For many years, our first-class setting department specialists have meticulously removed distortion from components following the quenching process. The Quantum E Scan Arm now offers an option that significantly compliments setting practices. By utilizing the scans captured by our state-of-the-art FARO equipment, our talented staff can make precise corrections to components, ensuring that they adhere precisely to our customers’ requirements.

2022 – NEW Vapour Degreaser

AHT Installs a brand new EVT manufactured SED Compliant vapour degreasing plant, which has near full recovery and recycling of vapour solvent.

2020 – AHT achieves Merit Nadcap accreditation

AHT achieves Merit Nadcap accreditation, following years of investment in plant and personnel, we are very proud of the prestigious award.

2022 – AHT achieves Merit Nadcap accreditation

AHT achieves Merit Nadcap accreditation, following years of investment in plant and personnel, we are very proud of the prestigious award.

2024 – 3 Times!

For the third successive time, AHT achieves Merit Nadcap accreditation, which is a testament to AHT’s professionalism and commitment to Quality.