HEAT TREATMENT SERVICES

ALLOY & ALUMINIUM HEAT TREATMENT SERVICES

We are a centre of excellence in alloy and aluminium heat treatment and offer a diverse heat treatment service, working in partnership with our clients.

Below is a short video on our manufacturing capabilities.

GENERAL ENQUIRIES

OUR FULL RANGE OF HEAT TREATMENT SERVICES

Degreasing

Our degreasing process involves removing unwanted oils, greases and other contaminants from metal surfaces. Our team uses a range of specialized cleaning agents and techniques to ensure that all surface contaminants are effectively removed before any further processing.

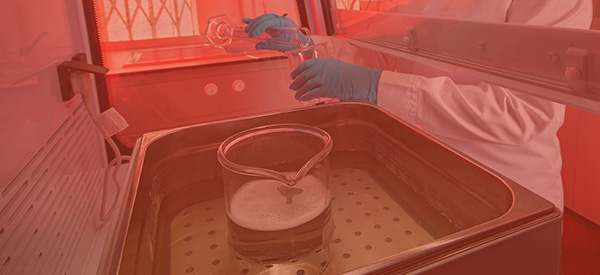

Dye-Penetrant Flaw Detection

We offer dye-penetrant flaw detection services to detect surface defects in metallic components. Our experienced technicians use a specialized dye solution to highlight any surface cracks or defects, enabling us to provide accurate defect assessments and remediation services.

Metallurgical Test Laboratory

Our metallurgical test laboratory services provide customers with detailed information on the properties and characteristics of their materials. Our experienced team can perform a range of metallurgical tests, including microstructure analysis, mechanical testing, and corrosion testing.

Precipitation Hardening/ Age Hardening

We offer precipitation hardening services to increase the strength and durability of metals. Our quenching process involves heating the metal to a high temperature, then rapidly cooling it to produce a hardened structure. This process can improve the properties of a range of materials, including aluminium, titanium, and stainless steel.

Setting (correcting material distortion)

Our material setting services involve correcting material distortion caused by heat treatment, welding or other processes. Our team uses specialized equipment and techniques to carefully manipulate the material back into its original shape, ensuring that any distortions are corrected without causing further damage.

Shotblast

Our shotblast services involve using abrasive particles to remove surface contaminants and provide a smooth, uniform surface finish. Our team uses specialized equipment and techniques to ensure that the desired finish is achieved, while minimizing the risk of damage to the material.

Solution Treatment

We offer solution treatment services to enhance the properties of metals by heating them to a high temperature and then rapidly cooling them. This process can improve the strength and durability of a range of metals, including aluminium, copper, and titanium.

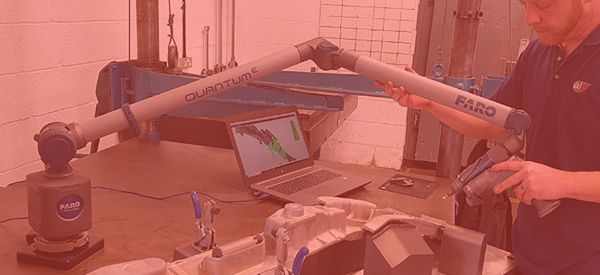

Material Testing & Evaluation

Our material testing and evaluation services provide customers with detailed information on the properties and characteristics of their materials. Our experienced team can perform a range of tests, including non-destructive testing, chemical analysis, and mechanical testing.